Adapter Selection Guide

At OneHydraulics, we often get phone calls from customers confused because their thread callouts are different than the nominal inch sizes or dash sizes shown in the catalogs or our online store. Below is a simple thread chart to help you correlate the thread callouts to the inch and dash sizes in our store.

Below this chart, you'll find descriptions and important information regarding each of the most common thread types we offer.

How to ID British Threads & Fittings

British Standard Pipe fittings are among the most popular of all foreign threads in the world today. These threads come in two versions: parallel (BSPP), and tapered (BSPT). The thread flank angle for both tapered and parallel British threads is 55°. Although BSP is a foreign thread, it isn’t actually metric.

This is why it comes in Imperial sizes: 1/8, 1/4, 1/2, 3/4, etc.

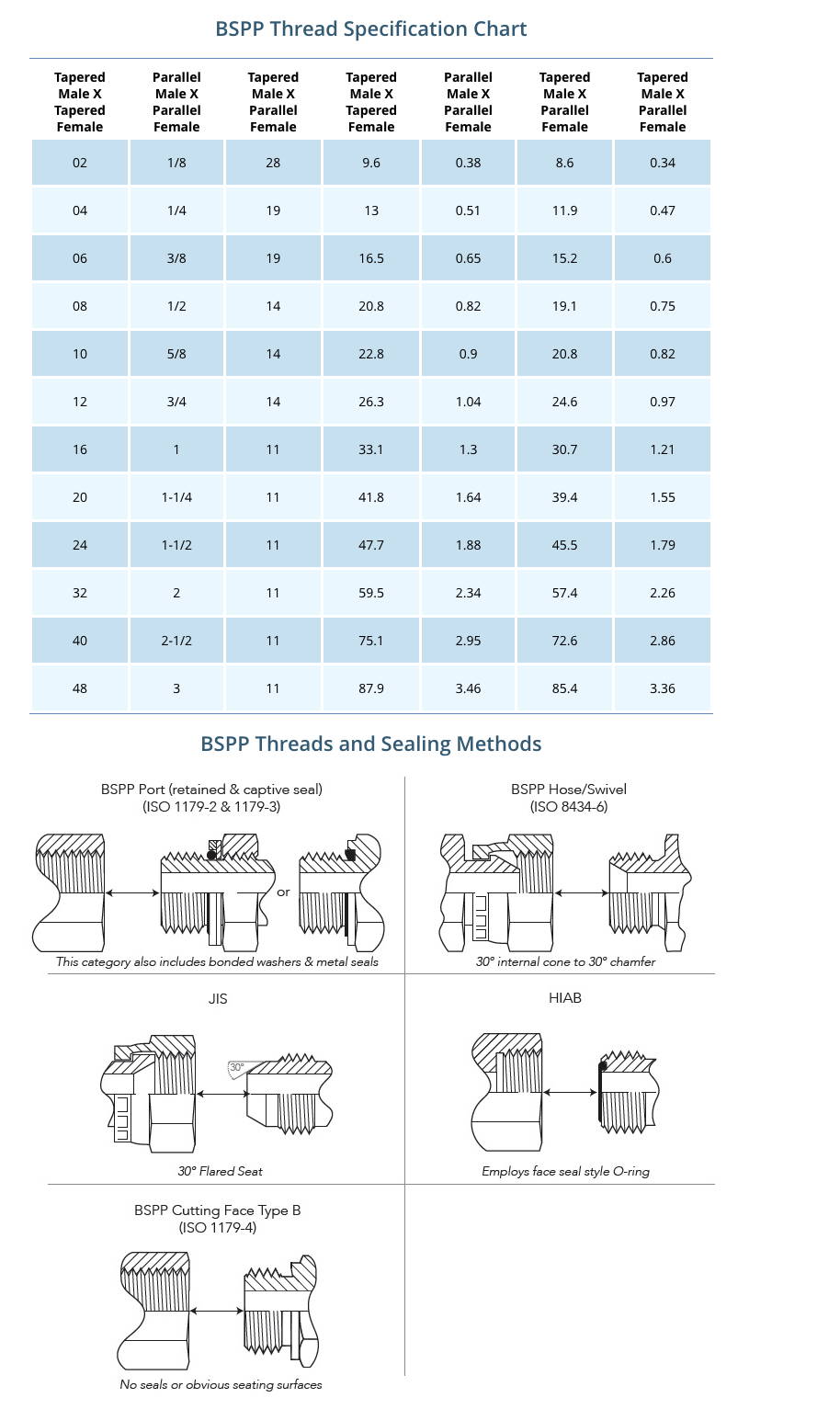

BSP parallel (BSPP) threads commonly seal via a 30° chamfer on the male thread to a 30° cone seat inside the female thread (swivel only). If it is a port application, an O-ring and washer, Elastomeric seal or a bonded washer are needed to achieve a proper seal for parallel threads. For tapered BSP threads (BSPT), a seal is accomplished via thread wedging with additional support from thread dope or tape. As previously mentioned, it is possible for a male BSPT (tapered) to thread into a female BSPP (parallel), so long as the female thread is fixed and not swivel (this is because the recessed cone seat could interfere with clearance).

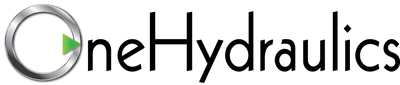

To identify a BSPP fitting complete the following steps:

- Confirm the thread is parallel or tapered.

- Determine the threads per inch (TPI) count using a thread gauge or calipers.

- Determine the thread O.D (male thread) or I.D (female thread) using calipers.

- Find a match on the adjacent chart by combining your O.D or I.D measurement with the TPI you measured.

- If a seal or angled sealing surface exists, use it to identify which specific type of British fitting it is on the chart to the right.

- To simplify this process, try our TGK (thread gauge kit).

Use the diagram below to confirm what type of British fitting you have. Use caution as “multi-purpose fittings” exist that accommodate 2 or more sealing styles in one fitting (such as Adaptall’s 9005ES series that can be used for BSPP port or swivel connection).

BSPP

British Standard Pipe Parallel

A captive seal is made using metal to metal angled surfaces, or a combination of metal to metal with an o-ring. Female swivel BSPP has a tapered nose flareless swivel where the seal occurs on the cone seat of the male connector. Similar but not interchangeable with NPSM/NPT since most sizes will have a different thread pitch and OD and thread forms are close, but not the same. Thread sealant is recommended when securing this connection style.

Thread sizes are expressed as fractional dimensions. "G" represents a parallel thread, for example BSPP 1/4-19 can be designated by G 1/4.

BSPT

British Standard Pipe Tapered

A captive seal is made using metal to metal angled surfaces, or a combination of metal to metal with an o-ring. Female swivel BSPP has a tapered nose flareless swivel where the seal occurs on the cone seat of the male connector. Similar but not interchangeable with NPSM/NPT since most sizes will have a different thread pitch and OD and thread forms are close, but not the same. Thread sealant is recommended when securing this connection style. BSPT male adapters are compatible with both BSPP and BSPT female ports.

Thread sizes are expressed as fractional dimensions. "R" represents a tapered thread, for example BSPT 1/4-19 can be designated by R 1/4.

NOTE: For British tapered threads (BSPT) caution should be taken as the most common tapered fitting in North America is NPT. The easiest way to distinguish any tapered fitting type from NPT is to verify if a chamfered sealing surface exists. If it does the fitting is most likely NPT. If not, it is either BSPT or Metric Taper (Metric Taper is far less common).

To verify the thread is BSPT, you would undergo the same steps as for a parallel British thread. First, verify the number of threads per inch. Second, measure the O.D. at the 3-4th thread from the end of the fitting. You can cross-reference your measurements to the following chart in order to verify the fitting is BSPT.

Code 61 & Code 62 Flanges

Code 61 Flange

SAE J518 4-Bolt Code 61 Flange

The Code 61 Flange is the standard 3000psi rated SAE J518 4-Bolt Flange. For higher pressure, use the 6000psi rated Code 62 flange. The overall design for the Code 61 & Code 62 Flanges is the same, but the flange head diameters and bolt hole spacing are larger for Code 62 flanges. The female port of the fitting is a smooth, unthreaded port with four bolt holes set in a rectangular pattern around the port. The male is a flanged head with a groove for an O-ring and either split or captive flange halves and bolt holes which match the port. The seal is made where the O-Ring is compressed between the flanged head and the flat surface of the port. The connection is held by threaded bolts.

Code 62 Flange

SAE J518 4-Bolt Code 62 Flange

The Code 62 Flange is the standard 6000psi rated SAE J518 4-Bolt Flange. For lower pressure, use the 3000psi rated Code 61 flange. The overall design for the Code 61 & Code 62 Flanges is the same, but the flange head diameters and bolt hole spacing are larger for Code 62 flanges. The female port of the fitting is a smooth, unthreaded port with four bolt holes set in a rectangular pattern around the port. The male is a flanged head with a groove for an O-ring and either split or captive flange halves and bolt holes which match the port. The seal is made where the O-Ring is compressed between the flanged head and the flat surface of the port. The connection is held by threaded bolts.

NPT

National Pipe Tapered

NPT is one of our most popular thread styles. NPT is a USA standard for tapered threads used on pipes and fittings. They are used to effectively seal pipes for fluid and gas transfer. Nominal pipe size can be identified by physically measuring the thread diameter, then subtracting 1/4". NPT connections rely on thread deformation, a metal to metal sealing design where the threads of the connectors themselves form together. This design is ideal for single assembly applications, and not recommended where connections will be assembled and disassembled frequently. Do not over-tighten. We recommend using a thread sealant with this type of connection style.

NPTF

National Pipe Tapered Fuel

Where traditional NPT threads have a small clearance between the crest and root of the mating threads requiring the use of sealant, the NPTF thread root does not allow this clearance. It contacts and deforms the mating thread crest. NPTF, or National Pipe Taper Fuel, style connections are widely used in fluid power systems. This type of connector is designed to provide a dry thread seal. However, lubricant is often still used to ease assembly. Most of the NPT adapters sold on OneHydraulics.com are NPTF style, but called out as just 'NPT'.

NPSM

National Pipe Straight Mechanical

NPSM, or National Pipe Straight Mechanical threads, are also often found in fluid power systems. The female component incorporates a straight, non-tapered thread with an inverted 30° chamfer of the male connector on the seat of the female. This is a mechanical seal. If and NPTF male is properly chamfered it will also seat with NPSM female connection. They are especially suited for manufacturers and end users that rely on versatility.

JIC

Joint Industry Council SAE J514

Both male and female JIC components are easily identified by their 37° tapered seats. This connection style is very popular in fluid power, especially hose end connections. The seal is made by establishing contact between the male flared and female coned seat. This is considered a mechanical connection. There are also SAE J512 45° connections, but those are more typical in automotive, refrigeration, and truck pipe systems. The JIC sold on OneHydraulics.com is the 37° style.

Note that -02, -03, -04, -05, -08, and -10 of SAE 37° and SAE 45° have the same threads, but NOT the same seat angles. Intermixing the two different types of fittings will result in leakage, so use care in measuring seat angles.

ORB

Straight Thread O-Ring Boss SAE J1926

Often called an "SAE" or "ORB" port, this thread style is recommended by the National Fire Protection Association (NFPA) for leak prevention. The male connection is a straight thread with an O-ring. The female port has a straight thread and a machined surface to provide a smooth, flat surface (minimum spot-face), along with a chamfer where the O-ring seats. It seals when the O-ring is compressed into the chamfer when mating the male connection. This is also considered a mechanical connection.

ORFS

O-Ring Face Seal SAE J1453

O-ring Face Seal connections are considered the best for leak control. The male connector has a straight thread and an O-ring in the face. The female has a straight thread and a machined flat face. The seal takes place by compressing the O-ring onto the flat face of the female, similar to the split flange type fitting. The threads maintain the connection mechanically.

DIN Tube Fittings

DIN fittings have a 24° tapered throat angle that exists inside the male threads. To achieve a tube connection, a tube nut is tightened over the metric threads (hardened pre-assembly fitting bodies are recommended for installation) forcing a ferrule or cutting ring to grip the tube. By having the nut securely fastened to the tube fitting, both compress the cutting ring which holds the assembly in place and creates a seal. This sealing style also includes Kobelco fittings which are essentially an L-series Metric thread with a 1.5mm thread pitch in all sizes.

DIN 24° fittings and accessories belong to one of three Pressure Classes:

LL series for Extra Light duty

L series for Light duty

S series for Heavy duty applications

Metric Fittings

Metric threads share many characteristics with British threads, so caution must be taken when attempting to differentiate the two. First, if the Metric thread is DIN 7631 it will have a 30° chamfer on the male thread, the same as a BSPP male. For fittings in port application, Metric fittings (ISO 9974) also mimic BSPP (ISO 1179) stud ends with the only difference being the threads. BSPT fittings closely resemble Metric taper fittings, although Metric taper is far less common. There are also variations of the sealing surfaces among different Metric fitting types that can create difficulty when attempting to identify.

For Metric parallel threads, taking a caliper reading of the threads outer diameter in millimetres (mm) will give a reading of the exact thread size but not the thread pitch. For example, a caliper reading of 12.03mm indicates it is very likely a 12mm thread. We still do not know however if it is 1.0 or 1.5 thread pitch (or some other pitch).

These steps should be taken in order to ensure you have successfully identified the proper Metric thread:

- Identify if the thread is parallel or tapered

- Determine the thread pitch in mm using a thread gauge or calipers (typically 1.0, 1.5, or 2.0, but other sizes do exist)

- Determine the thread O.D (male thread) or I.D (female thread) using calipers.

- Find the closest match on the adjacent chart (thread O.D and pitch combine into a “thread callout” such as M12 x 1.5 indicating a 12mm O.D with 1.5mm pitch)

- If a seal or angled sealing surface exists, use it to identify which specific type of Metric fitting it is on next page’s chart.

- To simplify this process, try Adaptall’s TGK (thread gauge kit).

If you have identified the fitting as having a Metric thread you still need to determine the version or style of Metric Fitting.

Metric Tapered Threads

If you have a Metric tapered thread, one would undergo the same initial steps for identification of thread pitch as a parallel Metric thread. Also similar to parallel Metric threads is that an O.D measurement will reveal the actual thread size (i.e. 18.01mm measurement means the thread is likely M18). However, to do this accurately with Tapered Metric threads one must measure the O.D at the third row of threads from the end of the fitting.